Pick, Place, Perfect: Robot Arms Redefining Automation Accuracy

- Don Bond

- June 24, 2025

- 6:43 am

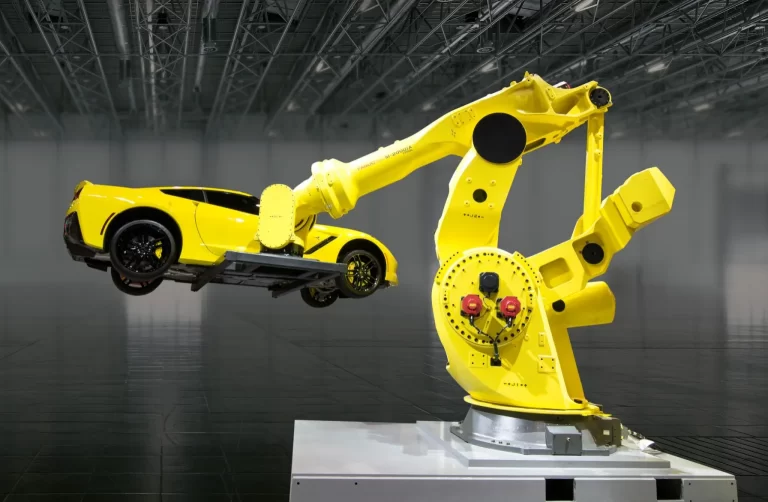

In the midst of modern manufacturing, robotic arms are rewriting the rules of production, mixing accuracy, safety and efficiency in ways that were unimaginable. These mechanical marvels – often known as robot arms become essential to industries all over the world due to the urgent necessity to reduce operating expenses without compromising on quality. Incorporating robotic arms into the manufacturing lines allows manufacturers to not just cut expenses but also improve work safety and efficiency. Find out how these machines have transformed the industrial landscape.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Factories have to constantly work to cut down on manufacturing errors, cut down on production waste, and cut down on the risk of workplace accidents. Robotic arms are designed to address these issues. Robots can eliminate costly errors and minimize the use of raw materials by performing repetitive tasks more precisely than human beings. For example, in industries with high volumes such as automotive manufacturing, robot arms ensure precise welding and parts placement to ensure perfect assembly each time. This precision can translate into significant savings because less damaged parts means less rework and waste.

The safety of robot arms is also an important element. A variety of manufacturing tasks like working with hazardous materials or using machines that are heavy pose a risk to workers. By deploying robot arms, companies can remove employees from the dangerous surroundings, dramatically decreasing the risk of workplace injuries. Robotic arms consist of a variety of movable joints that mimic human arm’s function. They can however operate with no risk of injuries. Equipped with programmable end effectors basically robotic hands, These machines are able to perform tasks such as grasping, spinning or welding in environments that are unsafe for humans.

The versatility of robot arms is an exciting development in a variety of industries. Robot arms can adapt to many different tasks, from assembly for automobiles to electronic production. They are programmable, which allows them to perform intricate operations like tending machines painting, painting, or fiberglass application, with unmatched accuracy. Robotic arms for warehousing have revolutionized palletizing by automating the loading of products onto pallets. Automation increases productivity and security because robot arms are able to work continuously and never get tired.

The rising popularity of cobots (collaborative robots) that work alongside human employees is one of the most thrilling innovations in this area. Cobots, which are equipped with a robotic arm, can interact seamlessly with humans unlike industrial robots which are generally restricted to cells. Cobots that have robotic arms can be used to complete routine or heavy lifting tasks in factories which allows human workers to focus on more challenging tasks. The cobots will stop or change their movement whenever they notice a worker close by.

Robotic arms have a profound impact on modern manufacturing, and not just in terms of safety, but also efficiency. They are vital for industries that require extreme precision for tasks like welding, assembly or even material handling. In the automotive industry for instance robotic arms can rotate and place parts during assembly to ensure perfect alignment without the need for human involvement. In the field of electronics, robots can be used to handle delicate components, which decreases the risk of damage and enhances the quality of output.

As the world of manufacturing continues to change, the role of robotic arms will only grow. Their ability to lower costs, improve safety, and adjust to different tasks makes them a cornerstone of the future of manufacturing. Robot arms, that combine cutting-edge technology and human creativity is not just a tool, but partners in progress. They inspire innovations and revolutionize the way in which the world is built.