Smooth Operator: Why MDF Boards Are Ideal For Furniture Making

- Don Bond

- April 26, 2024

- 1:21 pm

Woodworkers as well as DIY enthusiasts know that the right material choice can make or ruin a project. Solid wood is a timeless material, but engineered wood products like MDF (Medium Density Fiberboard) as well as melamine and particle boards can be a good alternative. Understanding the distinct characteristics and uses of each is vital to getting stunning and practical outcomes.

MDF Board: Smoothness, versatility and the Champion!

MDF boards are common in woodworking shops around the world. Its smooth even surface makes it easy to paint, stain or even apply veneers. In contrast to solid wood, MDF boards boast consistent density throughout, which eliminates concerns about cracking or warping. The consistent nature of MDF boards allows them to be used for intricate carvings, moldings as well as for the creation of intricate architectural designs.

MDF Boards Benefits

Smooth and flawless finishes The smooth surface allows an effortless application of veneer, paint or laminate. The result is an attractive, professional finish.

Workability: MDF boards are easy to cut, drill, and rout, making them perfect for intricate designs and complex projects.

MDF is a tough material that is used to serve a myriad of needs.

The versatility of MDF boards ranges from making furniture to building cabinets and even building architectural elements, MDF boards have a wide range of applications.

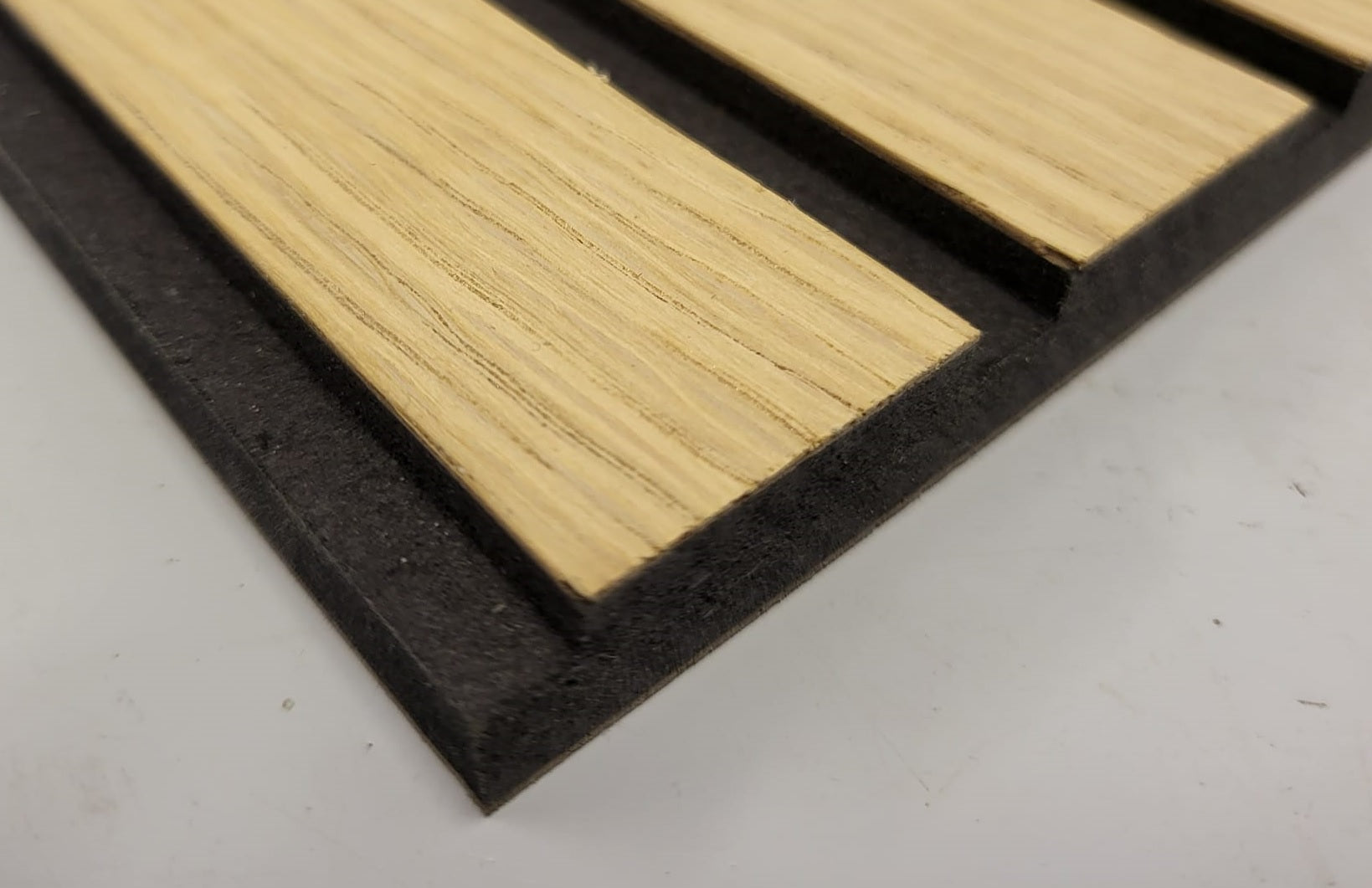

Melamine Sheets: Durability and style

Melamine sheets are a beautiful finish to MDF boards. They are constructed with the thin layer of melamine that is bonded to MDF, resulting in a tough and beautiful surface. Melamine finishes can be found in a wide range of colors, woodgrain patterns and textures.

The Benefits of Melamine Sheets:

It is stain-resistant and scratch resistant. The melamine finish provides great resistance to scratches stains and fading. They are suitable for areas that have a lot of traffic, such as bathrooms and kitchens.

Easy Maintenance: Melamine sheets require minimal upkeep. They can be maintained with a simple wipe down using a damp sponge.

Cost-effective Alternative: In comparison to solid wood and with similar appearance, melamine sheets provide a more budget-friendly option with a premium appearance.

Melamine sheets are versatile and can be utilized for numerous projects, including countertops and kitchen cabinets, as in addition to walls and furniture.

Budget-Friendly Particle Board

Although less popular than MDF and Melamine Particle Board is an excellent choice for projects in which the structural quality is more crucial than aesthetics. Particle board is made from compressed wood particles, and then bonded with resin, it provides an acceptable level of strength and stability.

Understanding Particle Board:

Cost-Effective: Particle board is the most affordable option among the three mentioned.

Application Limitations: The particle board’s rougher surface and low water resistance make it ideal for applications where aesthetics aren’t the primary issue. Examples include furniture pieces and subflooring.

If exposed to moisture, particle board will swell up and weaken its structural integrity. If you are working in conditions that are humid, it is important to use moisture-resistant types.

The Right Engineered Wood Panel

Selecting the right engineered panel for your project relies on its specific needs and requirements. This is a brief breakdown to help you decide:

MDF boards are renowned for their smooth surfaces, intricate designs, and overall flexibleness.

Melamine sheets provide the greatest combination of toughness, scratch resistance and pre-finished surfaces.

For projects that are budget-conscious and in which structural integrity of the project is the primary consideration, particleboard can be an option.

The Future of Woodworking – Engineered Wood Options

MDF sheets, melamine sheets and particle board are fantastic options for DIYers and woodworkers. Their versatility, affordability, and consistency of performance makes them an essential part of any project’s toolbox. Engineered wood solutions will continue to develop as technology progresses, expanding the creativity potential of future woodworking.